Capacity Constraints? Don’t Add New Lines Until You Consider These Questions.

The window business is good. So good that if you make your own insulating glass for residential windows, you’re probably feeling pressure to add cutting or IG lines to meet demand.

But what if you can:

- Get more production out of your existing equipment and labor?

- At the same time, also without adding new lines, lower labor, materials and fixed costs per unit?

Before you act, you should know the answer to both questions is: Yes, you can.

How to Increase Throughput with Your Current Lines

Start with Your Cutters

Most IG fabricators are sitting on significant unused cutting capacity because of unwanted downtime during glass type changes. This kills as much as 50 percent of your capacity.

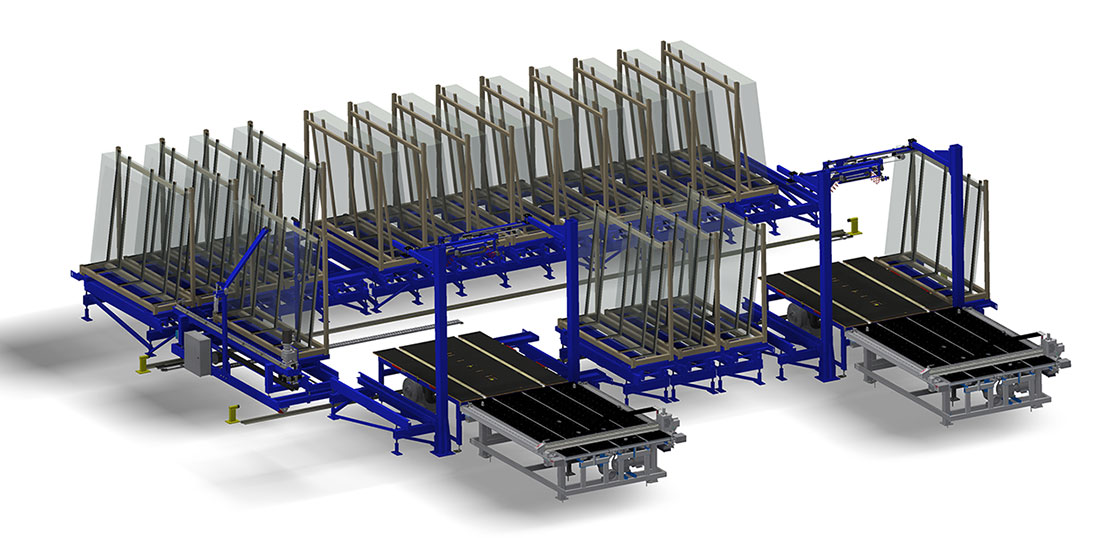

Supplying your CNC cutter with glass without delay eliminates this issue. And you can do it hour after hour, shift after shift, while simultaneously reducing loading labor, with our unique […]

Because of a long-term relationship with a partner/vendor, we’re able to reliably provide quality KN95 respirators and surgical masks at a competitive cost.

Because of a long-term relationship with a partner/vendor, we’re able to reliably provide quality KN95 respirators and surgical masks at a competitive cost. Ryan McHugh has been promoted to president of glass fabrication and gas filling equipment solutions company Integrated Automation Systems (IAS). His previous title was vice president of sales.

Ryan McHugh has been promoted to president of glass fabrication and gas filling equipment solutions company Integrated Automation Systems (IAS). His previous title was vice president of sales.

OptiLoad

OptiLoad