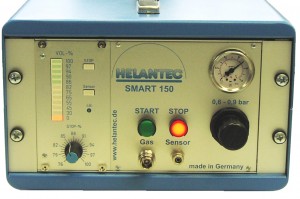

The SMART 150 uses tried and tested HELANTEC technology in an economical and easy-to-operate gas filling system. It is a single-line system with a capacity of approximately 200 units per week.

The gas concentration is continuously measured by the integrated gas analyzer during filling. As soon as the set gas concentration is reached, the process ends automatically.

The use of a pump and the optimized filling speed mean gas consumption is extremely low. The SMART 150 can be used for all gases and gas mixtures commonly used in insulating glass (argon, krypton, SF6, etc.). Adjustment of gas concentration is done by a rotary switch.

Because of its advanced technology, the reliable SMART 150 fills fast for its category.

HELANTEC SMART 150 Specifications

- Use in the production process for any gas types and gas mixtures

- Filling-lines: 1

- Capacity: Up to 200 units per week

- Microprocessor controlled

- Filling speed is fixed to approximately 9 liters/minute argon filling

- Pump: 1 to take analysis samples and increase speed

- One particle filter installed outside and easily

- Concentration measurement is online with special integrated analyzer

- Concentration display is online with LEDs

- Calibration of the analyzer is semi-automatic with calibration mode

- Filling stops automatically when the adjusted gas concentration is reached (factory made and adjustable between 70% and 100%)

- Accuracy of analyzer is better than 2% abs.

- Gas input pressure: 45 psi

- Gas input pressure control is optical and acoustic (if bottle pressure < 15 psi)

- Power supply 110-230V /50-60Hz

- Dimension: 11 x 13 x 7 inches

- Weight: 11 pounds

- Special accessories available for special applications