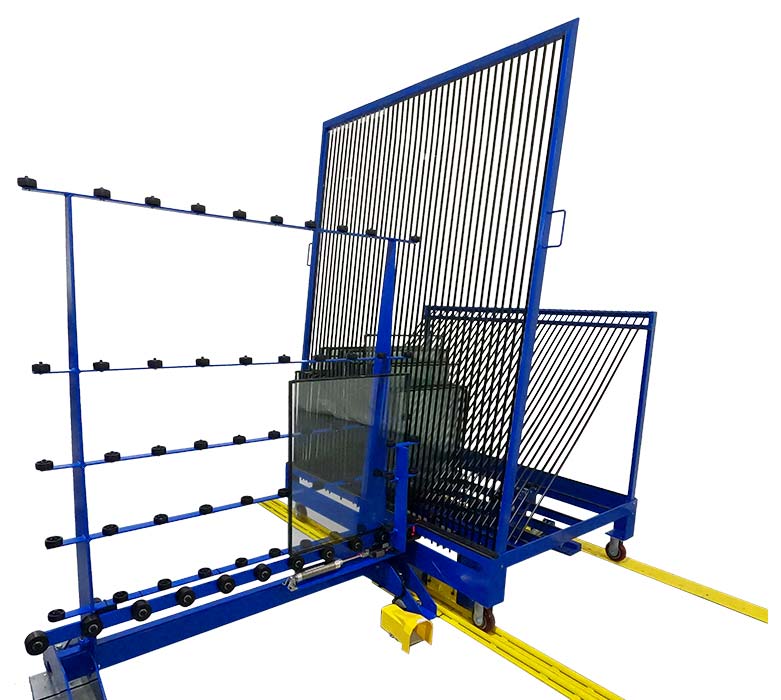

Rack Assist for Insulating Glass Units and Monolithic Glass

Chips and scratches in your insulating glass are annoying and costly—especially when they’re not discovered until after installation. The IAS Rack Assist system provides an easy way to rack and unrack insulating glass units and monolithic glass safely and without damage. With Rack Assist, you can:

- Minimize edge chips and scratches from manual racking

- Improve safety

- Decrease wear on racks

- Minimize sealant mess on racks

Use it Everywhere

Rack Assist can be used anywhere you rack and unrack IG units and monolithic glass. Because of its low price, you can deploy it across your plant! And it is available in three sizes: for residential, patio door and architectural and commercial glass.

Example applications include:

- Unracking at glazing lines

- Racking at the end of an insulating line

- Racking at the end of a tempering furnace

- Racking after fabrication processes

- Unracking to feed a furnace or fabrication equipment

- Unracking to feed an insulating line

- Re-sorting glass from one rack to another

How Rack Assist Works

- Engage rack

- Laser shows slot alignment

- Lock and unlock slot position with foot pedal

- Pneumatic loader perfectly aligns the slot and locks it in place

- Place the unit on the rollers and slide into the slot

- You can easily place units non-sequentially

- To unrack, just reverse the operation

Planned future capabilities include automatic features on the base system to drive units in and out of the racks and even index the rack, all while maintaining the attractive price point.

More Rack Assist Images